High Impact PolyStyrene sheets, or simply HIPS/PS sheets are alternatives to the more expensive Tamiya "Plaplate" brand. These sheets are highly flexible and bendable to a certain extent.

Applying heat makes it easy to bend HIPS/plaplates, but, once they harden, they become rather difficult to fix or manipulate further. Plaplates, being made of polystyrene, are rather flexible and can be bent to a point without breaking even without heat. Once bent, they would basically keep the bent shape, but maintain their flexibility until you're ready to "finalize" the shape. Plaplates have a more obvious grain or directionality (as compared to molded plastic), and it's worthwhile to take note of it because it can snap when bent along the grain. Bending it against the grain will at least prevent that during application of light bending force. Also, plaplates tend to crack when bent with the matte side up, whereas, paired with directionality the smooth and shiny side seems to prevent that when doing extreme bending.

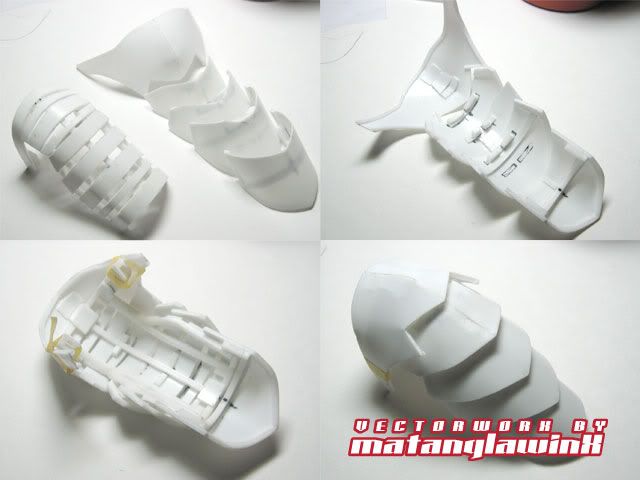

Here are a few samples of the armor parts I've done for the Ronin.

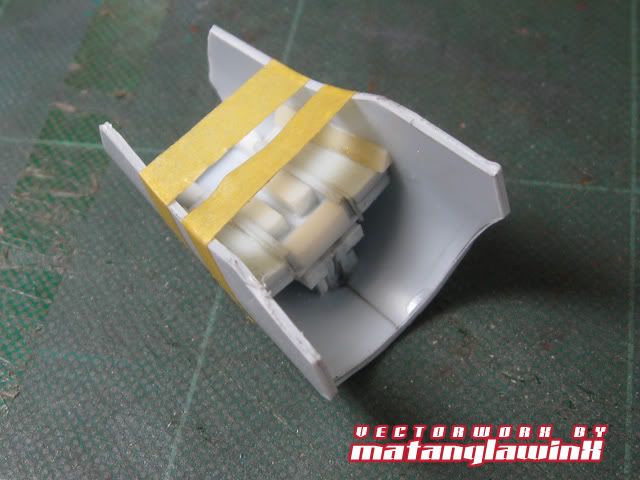

I usually use 0.5mm plates for most of these and reinforce them with 1.0mm beams to hold the shape, but 1.0mm is still flexible enough to be bent into shape. You can use a non-toothed pair of pliers cushioned with tissue or cloth for easier bending. The sample below is something I've done for the Scarlet JinX and is an add-on layer to an armor part. It's made up of two pieces of 1.0mm plaplates cemented together and was bent after the cement has fully cured (about a day).

When I modded the waist of the JinX to give it more height, I added plaplates on each side of the waist to give it more volume.

For the shape of the waist, I simply estimated the amount of curvature I needed to cut using a thinner pieces of plaplate as templates mounted on the original receptacle with double-sided tape, trimming those as I go. Then, I attached those templates to 1.0mm plates with double-sided tape which makes it easier to cut the plates more accurately but can be easily removed after the plates have been cut into shape.

This was slowly mounted on the stock receptacle with cement, allow enough time for one section to bond solidly before smoothing the rest of it along the receptacle curvature.

Since I'm still avoiding putty at this point, I had to bend the slab two ways; perpendicularly at first, then at an angle corresponding to the curve of the section I'm building to.

This particular section covers the side that encases the vulcan gun of the X-Walker.

Using larger pieces of HIPS trimmings, I roughly cut a shape (half of the actual shin guard) using one of the Warhammer pics as reference. Then used that as the template to create a whole one by reflecting the shape on its edge.

Then, with the usual heatless plaplate bending method, I bent the shin guards at the middle till they're supple enough and bent enough to keep that shape when cemented over the shin guard mounts. I marked the middle of the back of the shin guards to align it with the mounts.

I cemented it at the middle first, then cemented the sides, reinforcing it with triangular beams and securing it with tape as it cures. The setup should hold after a few hours of curing, but, at least 24 hours is the standard.

Plaplates and HIPS are easier to bend when they're large enough to be bent. Smaller pieces however are a bit finicky to bend into a curve properly, especially when they are already cut into shape. This piece is for the one of the Shin Guard face plates.

The trick is to bend it horizontally, then at 45 degrees alternately, then when it's soft enough, bend it vertically, instead of bending it vertically right away. Using a pipe or a round beam allows for an even bend.

With that, the piece is easier to mount on the curved surface of the faceplate.

The Skull face plate.

6 comments:

Hi, i'm new to your blog here. It's quite a revelation surfing through your posts :)

So anyway, i have a question if you don't mind - can you give me any information about (if you knew/have heard of this before, of course) Taiwan Pla Plate? Since i couldn't find HIPS around where i live - never mind the international online sellers from overseas, i don't even know how to contact (or buy) them - could that pla plate used as an alternative to the HIPS if they are also softer, or do you have any other alternative?

And there's another pla plate that bothers me actually - there's this guy who sell a pla plate with the name/brand called, "Pla Plate Styrene Sheet" - is that an official brand you're familiar with, or it's just a name? It bothers me because of the 'Styrene' word, which is just a shorten 'polystyrene', and therefore doesn't have any word that sounded like a 'brand'.

Thanks a lot for everything around here, btw! :D

"PlaPlate" is actually a brand of Tamiya polystyrene sheets, regardless, if it's called polystyrene, or styrene, you can use it as an alternative. Personally, however, the best way to know is to test or use the product yourself.

May I know where to get HIPs

Ok...is abs bending level good? Or it break more easier? What brand u use btw..

Ok..what brand u use? And is abs plates bendable as well?

ABS sheets are not as bendable as PS sheets. I have my own "brand" of PS sheets which I also sell, but it's out of stock at the moment.

Post a Comment